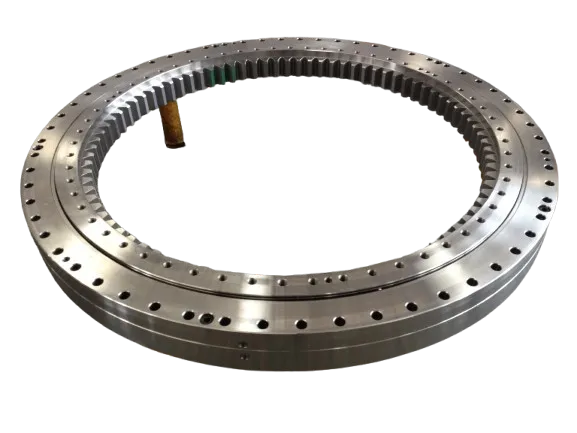

Slewing bearings are critical components in heavy machinery such as cranes, excavators, wind turbines, and industrial turntables. Designed to support axial, radial, and tilting moment loads, they must operate reliably under extreme conditions. However, like any mechanical component, slewing bearings are subject to wear, stress, and environmental influences that can lead to premature failure.

Slewing bearing failure can be caused by a variety of factors, often occurring prematurely due to issues that arise before traditional fatigue limits are reached.

Inadequate Lubrication: This is the leading cause of premature bearing failure. Without sufficient lubrication (often a heavy-duty, extreme pressure grease for slewing bearings), metal-to-metal contact occurs, leading to increased friction, wear, overheating, and ultimately surface damage like roughening, waviness, fine cracks, and flaking (spalling).

Incorrect Lubricant: Using the wrong type of grease (e.g., non-EP2 grease) can lead to lubricant film breakdown under high loads, causing excessive heat and accelerated wear.

Contamination of Lubricant: Dirt, sand, water, or other debris in the lubrication system act as abrasives, scratching or indenting raceways, which then develop fine cracks and spalling. Pressurized water jets during cleaning can also force water past seals, leading to corrosion.

Over-lubrication/Too Much Lubricant: While less common than under-lubrication, too much grease can also cause problems like excessive heat build-up.

Expired or Deteriorated Grease: Over time, grease can lose its lubricating properties.

Surface Flatness/Out-of-Flat Mounting Structure: Slewing bearings require infinitely rigid and flat mounting surfaces. If the structure distorts significantly under load or is out-of-flat, it applies loads to localized areas rather than distributing them evenly. This causes permanent deformation in the local area, leading to early failure.

Misalignment: Improper alignment during installation can cause uneven loading and increased wear.

Improper Preloading: If the bearing isn't preloaded correctly, it can lead to uneven loading and premature wear.

Bolt Torquing Errors: Incorrect tightening of mounting bolts can cause the bearing to bind or generate excessive heat. Loose bolts can lead to vibration, uneven stress, and even structural damage.

Foreign Objects During Installation: Debris introduced during installation can cause damage.

Exceeding Bearing Capacity: Applying loads that exceed the bearing's design capacity will cause permanent deformation and premature failure.

Uneven Load Distribution: When loads are not evenly distributed, certain areas of the bearing experience higher stress, leading to localized wear and deformation. This can be common in excavators that do most of their work in the same general area, leading to uneven wear patterns.

Excessive Impact Load: Sudden, heavy impacts can cause cracks or brinelling (permanent indentations) in the raceway.

Material Defects: Poor quality material with inclusions, voids, or cracks can lead to premature failure.

Manufacturing Errors: Bearings not manufactured to correct specifications or improperly heat-treated (e.g., insufficient hardening, too thin hardened layer) are prone to early wear and damage.

Poor Quality of Rolling Elements: If balls or rollers lack sufficient strength or wear resistance, they can wear or break prematurely.

Poor Sealing: Ineffective seals allow debris and moisture to enter the bearing, accelerating wear and corrosion.

Irregular or Insufficient Lubrication: As mentioned above, regular and correct lubrication is crucial.

Lack of Inspection: Failing to regularly inspect for signs of wear, damage, or abnormal sounds can allow problems to escalate until catastrophic failure.

Not Checking Bolt Torque: Mounting bolts can loosen over time, leading to instability and increased stress on the bearing.

Corrosion: Exposure to moisture, chemicals, saltwater, or extreme temperatures can cause the bearing components to corrode, leading to premature failure.

Harsh Operating Conditions: Dusty or humid environments can accelerate wear and promote contamination if seals are compromised.

Repeated Loading: Over time, the repeated loading and unloading cycles can cause cracks to develop in the bearing components, eventually leading to fatigue failure. This is more of a long-term wear process, but it can be accelerated by other factors like overloading or insufficient maintenance.

By understanding these common causes, operators and maintenance personnel can implement preventative measures to extend the life of slewing bearings and ensure the safe and efficient operation of machinery.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.