Choosing thin section bearings requires careful consideration of your application's specific needs. These bearings are prized for their space-saving and weight-reducing characteristics, but their "thinness" also makes them more sensitive to certain factors.

This is the most crucial step. Define:

Loads:

Radial Load: Perpendicular to the shaft axis.

Axial (Thrust) Load: Parallel to the shaft axis.

Moment Load: A load that tends to cause rotation about an axis (tilting). Thin section bearings can handle moment loads, but the type and configuration are critical.

Magnitude and Direction: Quantify these loads. Are they static or dynamic?

Speed (RPM): Operating speed and any peak speeds. This affects lubrication and heat generation.

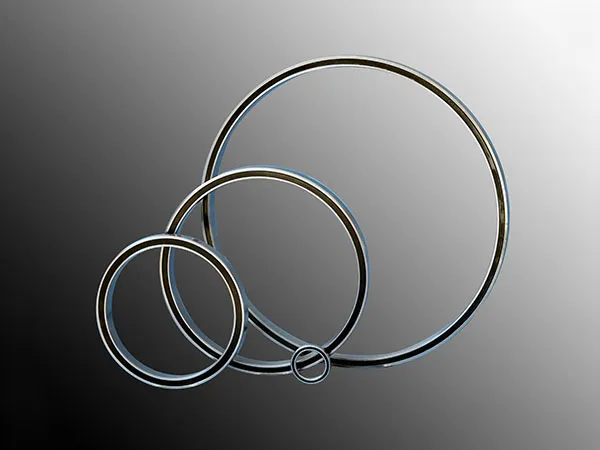

Space Envelope: What are the maximum allowable outer diameter (OD), inner diameter (ID), and width? This is often the primary driver for choosing thin section bearings.

Accuracy & Rigidity:

Runout: How much deviation from perfect rotation is acceptable?

Stiffness/Rigidity: How much will the bearing deflect under load? This is critical for precision applications.

Operating Environment:

Temperature: Operating range, extremes.

Contamination: Presence of dust, dirt, moisture, chemicals. This dictates sealing requirements.

Corrosion: Will the bearing be exposed to corrosive substances?

Life Expectancy: How many hours or revolutions does the bearing need to last? (L10 life)

Maintenance Requirements: Is relubrication possible or desired?

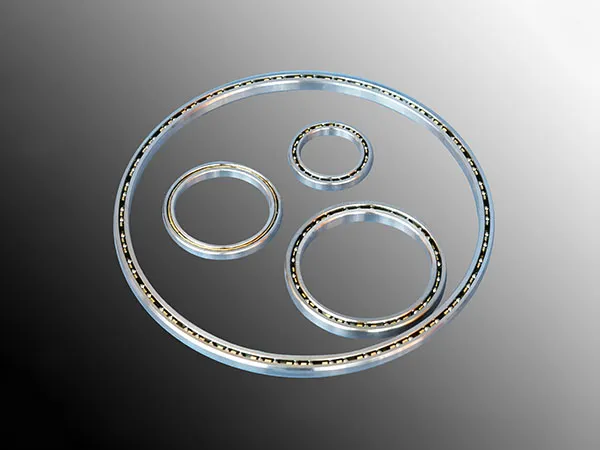

Thin section bearings come in three main contact types:

Type C (Radial Contact / Conrad):

Best for: Primarily radial loads. Can handle light to moderate thrust loads in one direction.

Characteristics: Deep groove, suitable for higher speeds.

Type A (Angular Contact):

Best for: Combined radial and thrust loads (thrust in one direction). Often used in pairs (duplexed) to handle thrust in both directions and increase moment capacity/stiffness.

Characteristics: Has a specific contact angle. Higher contact angles provide greater axial load capacity but lower radial capacity and speed capability.

Type X (Four-Point Contact):

Best for: Radial loads, thrust loads in either direction, and moment loads. A single Type X bearing can often replace two Type A bearings.

Characteristics: The gothic arch raceway geometry allows contact at four points. Generally, not for high-speed applications compared to Type C or A. Can exhibit higher friction.

Thin section bearings are often categorized by their cross-section (which remains constant as the bore size increases). Common series like Kaydon's Reali-Slim® or Koyo's K-series define these cross-sections (e.g., 3/16", 1/4", 5/16", 3/8", 1/2", 3/4", 1").

Based on your ID/OD constraints and the required load capacity (from manufacturer catalogs), select a series and bore size.

Standard: 52100 chrome steel is common.

Stainless Steel (e.g., 440C): For corrosion resistance. May have slightly lower load capacity.

Coatings: Thin dense chrome, black oxide, etc., for enhanced corrosion resistance or specific properties.

Hybrid Bearings (Ceramic Balls): Offer higher speeds, lower friction, increased rigidity, and electrical insulation. More expensive.

Lubrication:

Grease: Most common. Select based on temperature, speed, and load.

Oil: For higher speeds or specific temperature requirements.

Dry Film Lubricants: For vacuum, extreme temperatures, or where wet lubricants are undesirable.

Sealing:

Open (No Seals/Shields): Requires external sealing or a clean environment. Lowest friction.

Shields (Z, ZZ): Metal shields provide protection against larger particulate contamination. Non-contacting, so low added friction.

Seals (RS, 2RS): Elastomeric seals (e.g., nitrile, Viton) provide better protection against fine particles and moisture. Contacting seals add some friction and may limit speed.

Internal Clearance: The total distance one ring can move relative to the other.

Preload: An internal axial load applied during assembly to remove clearance.

Benefits: Increases stiffness, reduces runout, improves positioning accuracy, prevents ball skidding.

Considerations: Increases friction, heat, and reduces bearing life if excessive.

Angular contact bearings are often supplied with a specific preload or are designed to achieve it when mounted.

Thin section bearings are highly sensitive to out-of-roundness or distortion of the housing and shaft. Their thin rings will conform to the shape of the mating components.

Tolerances: Use manufacturer-recommended shaft and housing fits and tolerances.

Roundness: Ensure housing bores and shaft seats are perfectly round and concentric.

Support: The housing must be sufficiently rigid to support the bearing without distortion under load.

Handle with care to avoid distorting the thin rings.

Use proper tools (e.g., arbor press with correctly sized fitting tools that apply pressure to the correct ring).

Ensure even pressure during installation.

Verify alignment.

Bearing manufacturers (e.g., Kaydon, Koyo, SKF, NTN, RBC) provide detailed catalogs with load ratings, speed limits, dimensional data, and selection guides.

Don't hesitate to contact their application engineers for complex applications or if you're unsure. They can help with life calculations, lubrication recommendations, and custom solutions.

Key Takeaway for Thin Section Bearings:

Their primary advantage is saving space and weight. However, their thin rings mean that the design and precision of the housing and shaft, as well as proper mounting techniques, are far more critical than for standard, more robust bearings. Any imperfections in the mating components can easily distort the bearing, leading to increased friction, noise, and premature failure.

Optimizing Thin Section Bearing Torque for High-Speed Applications: Advanced Engineering Insights

2026-03-05 13:35Slewing Bearing Care in Wind Turbines: Expert Lubrication & Maintenance

2026-02-25 09:47Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.