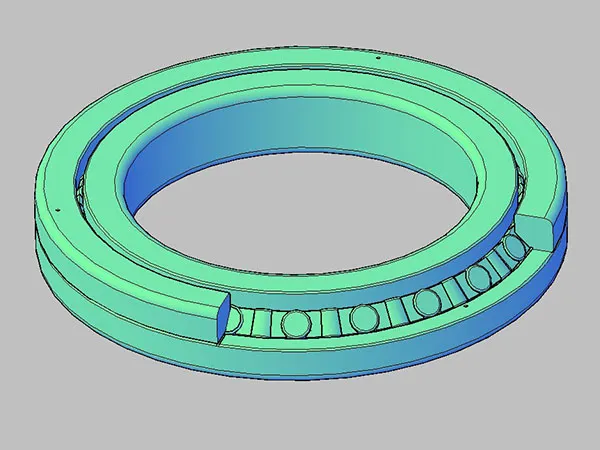

Precision crossed roller bearings are at the heart of modern high-precision machinery, from robotics and CNC equipment to aerospace and medical devices. Their unique design provides exceptional rigidity and smooth rotation, but even minor vibrations can compromise performance, reduce bearing lifespan, and affect operational accuracy. For engineers and maintenance teams, understanding how to control vibration is key to maintaining efficiency and reliability.

Vibration in precision crossed roller bearings can stem from several factors:

Manufacturing Variations – Tiny inconsistencies in roller or raceway geometry can create micro-vibrations during operation.

Installation Errors – Misalignment or uneven mounting surfaces can cause uneven load distribution, resulting in unwanted oscillations.

External Forces – Shock loads, uneven weight distribution, or high-speed operation can amplify vibration.

Lubrication Problems – Inadequate or improper lubrication increases friction, which intensifies vibrations and operational noise.

1. Ensure Precision Alignment

Proper alignment between the bearing and its housing is critical. Even slight misalignment can trigger oscillations. Utilize precision alignment tools and follow manufacturer torque specifications for optimal results.

2. Use High-Quality Lubrication

Selecting the right lubricant and maintaining consistent lubrication intervals is essential. Advanced greases or synthetic oils reduce friction and help dampen vibrations, especially in high-speed applications.

3. Optimize Load Distribution

Crossed roller bearings are engineered to handle both radial and axial loads. Ensuring the load is evenly distributed across rollers prevents localized stress, a primary source of vibration.

4. Implement Regular Maintenance

Routine inspection for wear, contamination, or lubrication breakdown can catch vibration issues early. Scheduled maintenance extends bearing lifespan and ensures smooth operation.

5. Consider Advanced Bearing Designs

Modern precision crossed roller bearings may include vibration-damping materials or innovative cage designs. Investing in these advanced bearings can significantly reduce operational vibration in demanding industrial settings.

Minimizing vibration in precision crossed roller bearings is more than just improving machine smoothness—it directly influences accuracy, component longevity, and production efficiency. By combining precise installation, quality lubrication, balanced load handling, and proactive maintenance, manufacturers can achieve optimal performance with minimal vibration.

For industries where precision is critical, mastering vibration control is a strategic advantage. Choosing the right bearing solutions today leads to lower maintenance costs and higher reliability tomorrow.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.