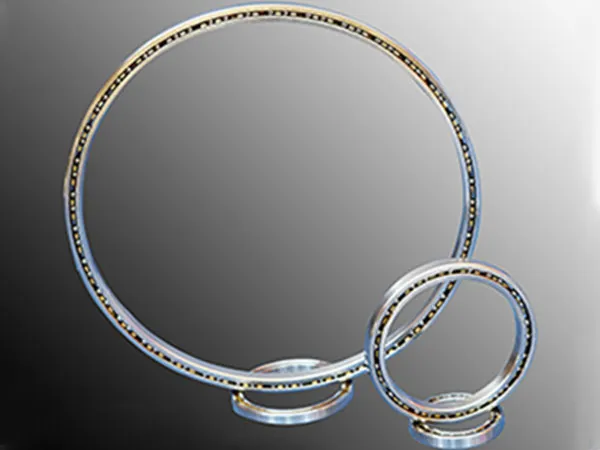

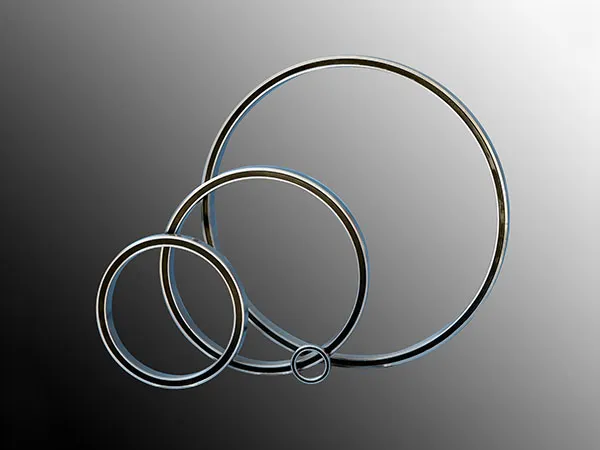

Thin section bearings are critical components in precision machinery, where compact design, high accuracy, and smooth operation are essential. They are widely used in robotics, aerospace, medical devices, semiconductor equipment, and industrial automation. Despite their slim profiles, these bearings must withstand significant loads and precise motion, which makes them particularly sensitive to installation errors, improper lubrication, and harsh operating conditions.

Extending the life of thin section bearings is not just about maintenance—it requires a systematic approach combining proper selection, precise installation, lubrication, and continuous monitoring. The following guide provides practical, actionable tips to maximize performance and prevent premature failure.

Selecting the correct bearing is the foundation of longevity. Using the wrong size, type, or material—even if it fits—can dramatically shorten service life. When choosing a thin section bearing, consider:

Load Capacity: Determine both radial and axial load requirements. Bearings running above rated capacity can overheat, deform, or fail prematurely.

Speed Ratings: For high-speed applications, bearings must tolerate elevated rotational speeds without generating excessive friction or vibration.

Environmental Conditions: Bearings exposed to dust, chemicals, moisture, or extreme temperatures may require stainless steel, ceramic, or coated materials.

Precision Requirements: High-precision equipment may demand ABEC 7–9 or ISO P4–P2 tolerance bearings.

Manufacturer Consultation: Discuss your application with the manufacturer. Sometimes a slightly larger bearing or a different material can dramatically improve lifespan.

Practical Tip: In high-vibration environments, consider bearings with reinforced cages or hybrid ceramic elements to reduce wear and heat.

Installation errors are a leading cause of bearing failure. Thin section bearings are especially vulnerable due to their delicate construction. Follow these practical steps:

Accurate Alignment: Use dial indicators, laser alignment tools, or precision gauges to align shafts and housings. Even 0.01 mm misalignment can cause uneven wear.

Controlled Mounting Force: Avoid hammering the bearing into place. Use hydraulic presses, alignment fixtures, or sleeve tools as recommended.

Clean Environment: Contaminants such as dust, dirt, or metal shavings accelerate pitting and reduce bearing life. Wipe surfaces and components thoroughly before assembly.

Correct Fastening: Apply torque as specified by the manufacturer. Over-tightening can deform the bearing, while under-tightening can cause uneven load distribution.

Common Mistake: Pressing bearings onto shafts using heat or brute force without proper tools often creates micro-cracks, leading to early failure.

Lubrication is the lifeblood of thin section bearings. Inadequate or contaminated lubrication can quickly cause overheating, surface wear, or corrosion. Key points:

Use Manufacturer-Approved Lubricants: Oils and greases are formulated for specific load, speed, and temperature ranges. Avoid generic products.

Establish Lubrication Intervals: For bearings in continuous operation, maintain regular schedules to prevent oil degradation.

Monitor Contamination: Dust, moisture, or metal particles can compromise lubrication. Use sealed bearings or shields in harsh environments.

Sealed or Pre-Lubricated Bearings: When maintenance access is difficult, sealed or pre-lubricated bearings can ensure consistent performance.

Practical Tip: Synthetic lubricants often provide better heat resistance and longer intervals between maintenance, especially for high-speed or high-temperature applications.

Thin section bearings often operate in tight tolerances and high-speed conditions, making them sensitive to abnormal loads or environmental changes. Effective monitoring can prevent catastrophic failure:

Temperature and Vibration Monitoring: Sudden increases in either parameter can indicate misalignment, lubrication failure, or overloading.

Avoid Shock Loads: Sudden axial or radial shocks, or abrupt start/stop cycles, can damage races and balls.

Protect Against Contaminants: Use shields, seals, or protective coatings in dusty, wet, or corrosive environments.

Condition-Based Maintenance: Implement sensors or monitoring systems to detect early signs of wear, such as unusual vibration or temperature spikes.

Industry Insight: Detecting a 10–15% increase in vibration early can prevent total bearing failure, saving hours of downtime and expensive replacements.

Even with proper installation and lubrication, regular inspection is essential. A proactive approach can catch problems before they escalate:

Visual Inspection: Look for surface pitting, discoloration, or corrosion.

Auditory Inspection: Unusual noises such as squealing or grinding indicate internal damage.

Dimensional Check: Measure clearance and rotational play to ensure tolerances are maintained.

Cleaning: Remove dust, debris, and old grease from both bearing and housing without using harsh solvents that could damage seals.

Practical Tip: Maintain an inspection log to track wear trends, helping predict replacement schedules and avoid unexpected downtime.

Use bearing sleeves or adapters to distribute load evenly across thin section bearings in high-stress applications.

Avoid frequent thermal cycling, which can cause differential expansion and premature fatigue.

For precision machinery, consider hybrid bearings (ceramic balls with steel races) to reduce friction, heat, and wear.

Implement redundant monitoring in critical systems to ensure small issues are caught early.

Extending the life of thin section bearings is not just about following generic maintenance rules—it requires a hands-on, practical approach:

Select the right bearing for load, speed, and environment.

Install with precision and cleanliness.

Maintain proper lubrication and sealing.

Monitor operating conditions and respond quickly to anomalies.

Conduct scheduled cleaning and inspections.

By combining these strategies, businesses can maximize bearing lifespan, reduce maintenance costs, and improve machinery reliability, even in high-precision or space-constrained applications. Small adjustments in care and handling today can prevent major downtime tomorrow.

How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Effects of Surface Roughness on Slewing Bearing Performance

2025-12-27 17:21Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.