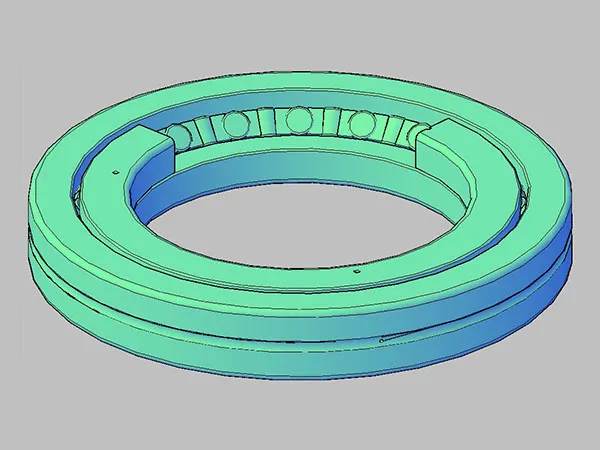

Precision crossed roller bearings are essential components in machinery that demand high rotational accuracy and load capacity, including robotics, CNC machines, and medical imaging equipment. Even with their robust design, improper maintenance can lead to unexpected downtime, reduced precision, and costly repairs. By implementing the right maintenance strategies, you can significantly extend the life of your precision crossed roller bearings and maintain smooth, accurate operation. Here are six essential tips to keep your bearings in top condition.

1. Conduct Regular Inspections

Routine inspections are the first step in preventing bearing failure. Check for unusual noises, vibration, or resistance during rotation. Early detection of minor issues such as wear, corrosion, or contamination can save your equipment from expensive downtime and extend the bearing’s lifespan.

2. Apply Proper Lubrication

Lubrication is critical for reducing friction and preventing wear. Always use the grease or oil recommended by the bearing manufacturer. Avoid over-lubrication, as excess lubricant can attract contaminants. For high-speed applications, synthetic lubricants are preferred because they maintain stability under extreme operating conditions. Make sure to clean the bearing surface before applying fresh lubricant for optimal performance.

3. Maintain a Clean Environment

Precision crossed roller bearings are highly sensitive to dust, metal particles, and moisture. Handle bearings in a clean environment and use protective covers or seals whenever possible. Even small amounts of contamination can compromise accuracy and lead to premature failure.

4. Avoid Excessive Load and Misalignment

These bearings are engineered for specific load and alignment conditions. Subjecting them to excessive radial or axial loads, shock loads, or misaligned installation can result in uneven wear, increased friction, and reduced precision. Always follow manufacturer guidelines for proper mounting and load limits.

5. Monitor Temperature and Operating Conditions

Excessive heat can damage bearing surfaces and degrade lubrication. Ensure your equipment operates within the recommended temperature range. For high-speed or heavy-load applications, monitor temperatures regularly and implement cooling solutions if necessary to maintain optimal performance.

6. Replace Bearings Promptly

Even with excellent maintenance, bearings eventually reach the end of their service life. Replacing worn or damaged precision crossed roller bearings promptly prevents collateral damage to other machinery components and ensures reliable operation.

Proper maintenance of precision crossed roller bearings is straightforward but essential. By following these six tips—regular inspections, correct lubrication, clean handling, proper load management, temperature monitoring, and timely replacement—you can maximize bearing lifespan, reduce downtime, and maintain high-precision performance. Implementing these strategies not only saves costs but also ensures your industrial equipment continues to operate at peak efficiency.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.