Precision crossed roller bearings are essential for machinery that demands high rigidity, smooth rotation, and precise positioning. Widely used in CNC machines, robotic arms, medical equipment, and precision automation systems, these bearings ensure consistent performance when installed correctly. Incorrect installation, however, can lead to early wear, vibrations, and unexpected downtime. This guide provides actionable steps to install precision crossed roller bearings safely and efficiently.

1. Learn the Bearing Structure and Function

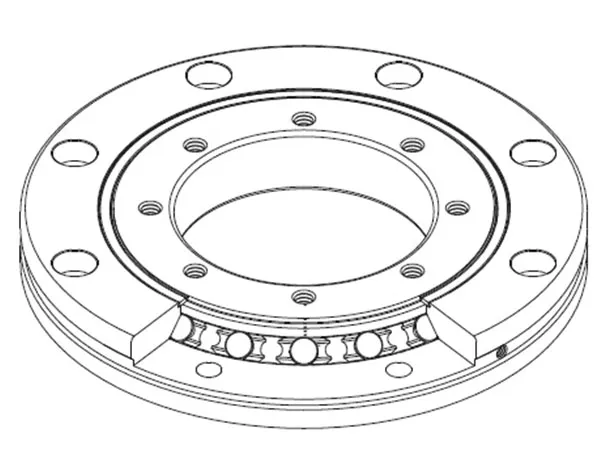

Crossed roller bearings consist of cylindrical rollers arranged alternately at right angles between the inner and outer rings. This design allows the bearing to handle radial, axial, and moment loads simultaneously, making accurate alignment crucial. Always check the manufacturer’s datasheet to verify the bearing type, size, tolerance, and load rating before installation.

2. Prepare Clean and Accurate Mounting Surfaces

The bearing’s performance depends on the quality of the shaft and housing surfaces. Make sure all surfaces are clean, smooth, and free from burrs, dust, or oil residues. Use precision cleaning methods, lint-free cloths, and solvents recommended by the manufacturer. Measure shaft diameters and housing dimensions with calipers or micrometers to ensure they meet tolerance standards.

3. Handle Bearings Carefully

Precision crossed roller bearings are highly sensitive to shocks and contamination. Always handle bearings with clean gloves or tools, and avoid direct impact on rollers. Even small particles or grease contamination can significantly shorten the bearing’s service life.

4. Ensure Accurate Alignment and Seating

Correct alignment is key to optimal performance. Misalignment can cause uneven load distribution, vibration, noise, and premature wear. Use precision tools such as dial indicators, torque wrenches, or alignment jigs. Mount inner and outer rings evenly, applying uniform pressure to prevent roller damage.

5. Apply the Right Lubrication

Lubrication is essential for reducing friction, preventing wear, and avoiding corrosion. Follow the manufacturer’s guidance on lubricant type and amount. High-quality grease or precision oil designed for crossed roller bearings is recommended. Avoid over-lubrication, which can lead to overheating or leakage.

6. Test Operation Before Full Load

After installation, rotate the bearing manually to check for smooth operation and uniform contact. Listen for any unusual noise or feel for roughness. Gradually apply the operational load while monitoring temperature and vibration to confirm proper installation.

7. Implement Regular Maintenance

Even the best-installed bearings need periodic inspection. Monitor lubrication levels, check for wear, and clean any contamination. Routine maintenance ensures reliability and prolongs service life, preventing unexpected machinery downtime.

Installing precision crossed roller bearings correctly is critical for high-performance machinery. Proper surface preparation, careful handling, precise alignment, and appropriate lubrication ensure smooth operation and extended lifespan. Following these steps helps reduce maintenance costs, prevent operational failures, and maximize the efficiency of CNC machines, robotics, medical equipment, and other precision systems.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.