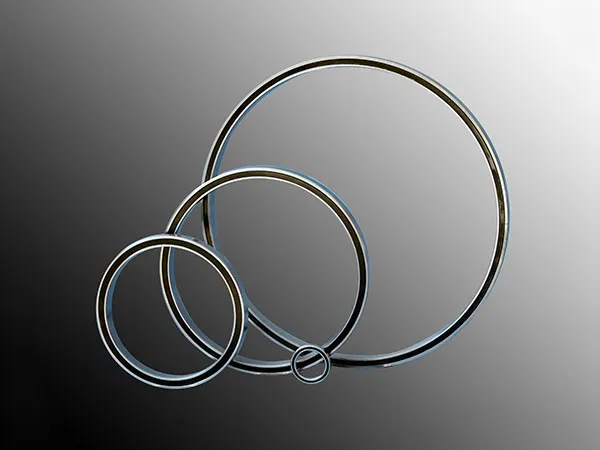

Unlike standard bearings, thin section bearings are not just smaller in size — they are engineered to deliver exceptional performance within extremely limited spaces, making them indispensable in modern precision machinery.

As the name suggests, thin section ball bearings feature a significantly smaller cross-sectional thickness (both radially and axially) compared to traditional bearings of the same inner diameter.

This means the difference between the inner and outer diameters is minimal, resulting in a compact, lightweight bearing that still maintains high load capacity and precision.

Their unique structure allows engineers to reduce both the weight and overall dimensions of equipment without sacrificing strength or stability.

Outstanding Space Efficiency

Thin section bearings excel in applications where installation space is limited. Their compact profile allows for more flexible and efficient equipment design.

Lightweight Design

With less material required, these bearings are significantly lighter than standard options — a critical benefit for aerospace, robotics, and medical equipment where every gram matters.

High Precision and Stability

Despite their small cross-section, these bearings are manufactured with tight tolerances, ensuring smooth rotation, minimal vibration, and long-term operational accuracy.

Low Friction and Energy Savings

Optimized internal geometry reduces contact and friction, helping lower energy consumption and extend the service life of the entire system.

Versatile Design Options

Available in open, sealed, and angular contact configurations, thin section bearings can be customized to meet diverse application requirements.

Selecting the ideal thin section bearing requires attention to several crucial factors:

Size Series:

Various size series (such as Kaydon’s Reali-Slim® or ISO-standard series) define the ratio between inner and outer diameters and width.

Inner & Outer Diameter:

Choose based on the shaft and housing dimensions of your equipment.

Width & Cross-Section:

Influences the bearing’s rigidity and load capacity.

Material Selection:

AISI 52100 bearing steel – standard choice for general industrial use.

AISI 440C stainless steel – ideal for corrosive or humid environments.

Ceramic hybrids – perfect for high-speed or non-magnetic applications.

Precision Grade:

Follow ABEC standards (ABEC-1 to ABEC-7); higher grades ensure tighter tolerances and smoother operation.

Load Ratings

Evaluate both radial and axial load capacities based on your working conditions.

Seal Type:

Options include open (no seal), shielded (ZZ), or sealed (2RS) bearings to protect against contamination.

Preload and Clearance:

Adjusting preload or internal clearance can improve rigidity, reduce noise, and enhance bearing life.

Thanks to their precision and lightweight design, thin section bearings are widely used in:

Aerospace Systems: radar antennas, flight control systems, satellites

Robotics and Automation: robotic joints, precision arms, automation lines

Medical Equipment: CT scanners, surgical robots, dental tools

Semiconductor Machinery: wafer transfer systems, precision measurement tools

Optical and Imaging Devices: telescopes, camera gimbals, optical instruments

Defense and Military Systems: targeting systems, guidance units, sensors

Thin section ball bearings represent the perfect fusion of precision engineering, compact design, and lightweight performance.

As industries continue to push for miniaturization and efficiency, these bearings will play an even greater role in the next generation of high-performance machinery.

Our company specializes in providing customized thin section bearing solutions that meet the most demanding industrial requirements.

If you need assistance selecting or designing the right bearing for your project, contact our engineering team today — we’ll help you find the optimal solution for your application.Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.