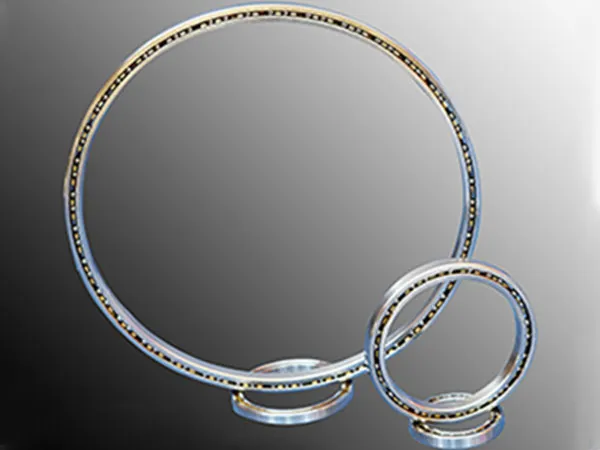

At the heart of modern industrial operations, precision mechanical design demands unparalleled efficiency and reliability. Thin section bearings, with their unique advantages of being lightweight, slim, and highly precise, are emerging as the preferred choice in sectors with stringent space and weight constraints—such as aerospace, medical devices, robotics, and high-end semiconductor manufacturing. However, to truly unlock the potential of these precision components and ensure their long-term service life, selecting high-quality bearings alone is insufficient—precise installation and alignment are the critical factors determining their performance and longevity.

This article delves into the core strategies and practical techniques for aligning thin section bearings, empowering your engineering team to effectively avoid installation pitfalls, significantly enhance equipment operational efficiency, and minimize long-term maintenance costs.

The geometric characteristics of thin-section bearings make them exceptionally sensitive to even minor installation deviations. Their slender cross-section makes uniform load distribution fundamental to performance. Once misalignment occurs, a chain reaction rapidly unfolds:

Stress Concentration and Accelerated Failure: Load distribution becomes uneven across raceways and rolling elements, creating localized high-stress zones that accelerate material fatigue and lead to premature bearing failure.

Noise, Vibration, and Increased Energy Consumption: Irregular load distribution and friction generate harsh noise and unnecessary vibration, directly impacting equipment smoothness while increasing system friction. This causes elevated operating temperatures and significant energy loss.

Precision Degradation: In applications demanding high accuracy, any bearing misalignment directly compromises equipment positioning precision and repeatability, potentially affecting product quality.

Soaring Maintenance Costs: Frequent failures and replacements not only interrupt production but also incur substantial repair and downtime expenses.

Ensuring optimal performance of thin-section bearings requires meticulous attention, akin to performing precision surgery.

1. “Ultimate” Preparation of Mounting Surfaces

Foundational work before installation is the starting point for all subsequent success.

Spotless Cleanliness: Ensure shafts, bearing housings, and all mating surfaces are thoroughly clean—free of any visible or hidden dust, chips, burrs, or oil residue.

Even micron-level contaminants can cause permanent indentations on bearing raceways under heavy loads.

Surface Texture: Strictly verify surface roughness on mating surfaces against manufacturer specifications. Excessively coarse surfaces may cause loose fits, while overly fine surfaces may hinder adequate oil film formation.

Zero Tolerance for Dimensional & Geometric Tolerances: Employ high-precision measuring instruments, such as coordinate measuring machines (CMMs), to comprehensively inspect shaft and bearing housing diameters, roundness, cylindricity, and end-face perpendicularity. Any deviation beyond tolerance limits will directly and negatively impact bearing alignment.

Precise Chamfering: Ensure proper chamfers are present at shaft shoulders and bearing housing bore entrances. This facilitates smooth bearing installation while effectively preventing damage to bearing edges during mounting.

2. Selection and Execution of “Scientific” Installation Methods

Selecting and precisely executing the installation method according to bearing type and fit requirements is critical.

Heat Mounting (Interference Fit): For bearings with significant interference, use precision-temperature-controlled induction heaters or specialized heating furnaces to uniformly expand the bearing. Heating temperatures must strictly adhere to manufacturer recommendations to prevent material degradation. Open flames or localized heating are strictly prohibited.

Cold Pressing Method (Slight Interference or Clearance Fit): For smaller bearings or those with moderate interference, use custom hydraulic tools or mechanical press-fit equipment. Critical principles include applying force uniformly and steadily, directly to the full end face of the bearing inner or outer ring. Striking the rolling elements, cage, or bearing sides is strictly prohibited to prevent deformation or damage.

Uniform Force Application Principle: Regardless of the method employed, the core principle is to ensure load distribution is uniform, preventing bearing tilt or any form of localized stress.

3. Seamless Alignment in Shaft Systems

Precise shaft alignment is a decisive factor for extended bearing service life.

Coaxiality is Paramount: In applications involving multi-section shaft connections, ensure ultimate coaxiality between all shaft sections connected to thin-section bearings. Laser alignment instruments are ideal tools for high-precision measurement and adjustment.

Axial Securing: Thin-section bearings typically require reliable axial securing mechanisms to prevent displacement under high-speed or variable load conditions.

Common securing methods include shaft shoulders, thrust washers, or retaining rings. Ensure these fixtures are tight, evenly loaded, and show no signs of looseness.

4. The Delicate Balance of Radial and Axial Clearance

Internal clearance in thin-section bearings profoundly impacts their operational characteristics.

Preload Strategy: In applications demanding ultimate rigidity and rotational precision, apply minimal preload to thin-section bearings per manufacturer guidelines. Preload eliminates clearance, but excessive force overloads the bearing internally, accelerating wear—strict control is essential.

Operating Clearance: Thoroughly consider thermal expansion and contraction effects at actual operating temperatures. Ensure bearings maintain adequate operating clearance within the equipment's normal temperature range to prevent seizure or overheating.

5. Lubrication: The Finishing Touch

Even with perfect alignment during installation, proper lubrication remains indispensable.

Precise Selection: Carefully choose the most suitable grease or oil based on bearing type, operating speed, ambient temperature, load magnitude, and specific application requirements.

Moderation is Key: Thin-section bearings typically require only minimal lubricant. Excessive lubrication increases internal agitation resistance, causing temperature rise and potentially adversely affecting high-speed bearings.

Aligning thin-section bearings transcends mere technical execution—it embodies an engineering philosophy of relentless refinement. From meticulous preparatory work to methodical installation procedures and ongoing operational monitoring, every step is critical. By systematically implementing the above optimization strategies, your engineering team can significantly enhance the operational efficiency of thin-section bearings, extend their service life, and ultimately elevate equipment reliability and production efficiency.

Continuous maintenance inspections and specialized operator training are essential to ensuring the long-term success of these precision engineering investments.

Should you encounter any challenges in selecting, installing, maintaining, or troubleshooting thin-section bearings, our expert technical team stands ready to provide cutting-edge product solutions and unparalleled technical support.

Optimizing Thin Section Bearing Torque for High-Speed Applications: Advanced Engineering Insights

2026-03-05 13:35Slewing Bearing Care in Wind Turbines: Expert Lubrication & Maintenance

2026-02-25 09:47Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.