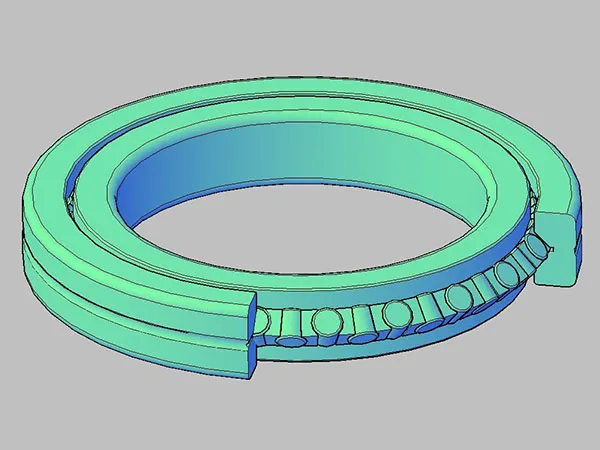

The "life" of a precision crossed roller bearing, like any rolling element bearing, generally refers to its fatigue life. This is the number of revolutions or operating hours a bearing can achieve before the first signs of material fatigue, such as spalling or flaking, appear on its raceways or rolling elements.

Precision crossed roller bearings are critical components in high-accuracy applications, and their longevity is paramount. Here's a comprehensive guide to improving their life, based on best practices.

Accurate Load Calculation: This is the foundational step. Understand the magnitude, direction (radial, axial, moment), and combination of loads the bearing will experience. Overloading is a major cause of premature failure.

Environmental Conditions: Consider temperature, humidity, dust, and exposure to contaminants. Choose bearings with appropriate materials, seals (if applicable in the surrounding design, as crossed roller bearings themselves typically don't have integrated seals), and lubricants for the operating environment.

Precision Requirements: Select the appropriate precision class for your application. Higher precision bearings often require more precise mounting and handling.

Stiffness and Preload: Crossed roller bearings offer high stiffness. Proper preloading during design and assembly is crucial. Too little preload can lead to clearance and vibration, while excessive preload can generate heat and reduce life.

Anti-Creep Mechanisms: For applications with high acceleration/deceleration, uneven loading, or vertical/inclined strokes, consider bearings with anti-creep mechanisms to prevent roller slippage and wear.

Mating Component Design: The rigidity and accuracy of the housing, shaft, and presser flanges are critical. Insufficient rigidity can lead to uneven load distribution and bearing deformation. Ensure mating surfaces are clean, free of burrs, and meet specified tolerances for roundness, straightness, and surface roughness.

Cleanliness is Key: Before installation, thoroughly clean the bearing, shaft, housing, and all mating components. Remove any burrs, dirt, oil stains, and processing residues. Even minute particles can cause significant damage and premature failure.

Handle with Care: Precision bearings are delicate. Avoid dropping, striking, or applying direct force (like hammering) to the bearing or its outer/inner rings, as this can cause damage to raceways and rolling elements. Use appropriate lifting and handling tools.

Follow Manufacturer's Instructions: Always adhere strictly to the bearing manufacturer's specific installation guidelines for your bearing type and model. These instructions cover critical aspects like mounting direction, tightening sequences, and torque specifications for bolts.

Controlled Installation Force: Use presses or other appropriate installation tools to apply uniform force. If a press fit is required, ensure the pressure is applied only to the ring being pressed. Avoid overheating during shrink-fit installation (typically not exceeding 120°C for bearings).

Proper Alignment: Ensure precise axial, radial, and angular alignment during installation. Misalignment can lead to uneven stress, increased friction, heat generation, and reduced life. Use alignment tools when necessary.

Initial Lubrication: Before installation, apply the recommended lubricant to the bearing. This helps reduce friction and provides initial protection.

Choose the Right Lubricant: Select the type (grease or oil) and grade of lubricant recommended by the bearing manufacturer, considering operating temperature, speed, load, and environmental conditions. For most crossed roller bearings, low-viscosity greases (e.g., lithium-soap-based #00 grease) or CLP/HLP oils are suitable.

Proper Quantity: Over-lubrication can be as detrimental as under-lubrication. Excess lubricant can increase internal friction and generate heat, shortening life.

Under-lubrication leads to increased friction and wear. Follow manufacturer guidelines for fill quantity.

Application Method: Apply lubricant directly to the raceways and ensure it spreads evenly. For grease, gently stroke the bearing several times to distribute it.

Do Not Mix Lubricants: Mixing different types or brands of lubricants can lead to incompatibilities and reduced performance.

Regular Relubrication: Establish a regular relubrication schedule based on operating conditions, environment, and manufacturer recommendations. Monitor the condition of the lubricant.

Cleanliness During Relubrication: Ensure that no contaminants enter the bearing during the relubrication process.

Regular Inspection: Routinely inspect the bearings for any signs of wear, damage, unusual noises, vibrations, or changes in performance. Early detection of problems can prevent catastrophic failures.

Contamination Control: Protect the bearing from contaminants like dust, dirt, moisture, and corrosive substances. Use bellows, covers, or seals in the surrounding machinery to create a clean operating environment. Keep the bearing area clean.

Temperature Monitoring: Monitor the bearing's operating temperature. Excessive heat can degrade lubricants and bearing materials, leading to premature failure.

Identify and address the root cause of overheating.

Addressing Cage Creep: If cage creep is observed (rollers not rolling but slipping), identify the cause (e.g., high acceleration, uneven preload, mounting orientation) and address it. Anti-creep mechanisms can significantly mitigate this issue.

Proactive Replacement: Even with proper maintenance, bearings have a finite life. Keep track of service life and consider proactive replacement based on predicted life calculations or observed wear patterns, especially in critical applications.

Professional Consultation: For complex issues or unusual operating conditions, consult with bearing manufacturers or experienced technical specialists.

By diligently adhering to these guidelines, you can significantly extend the operational life, maintain the precision, and ensure the reliability of precision crossed roller bearings in your applications.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.