Slewing bearings are critical components in large equipment like cranes, excavators, and wind turbines, enabling rotation and supporting significant loads. A robust replacement strategy is essential to minimize downtime, ensure safety, and optimize operational costs. This strategy involves a combination of proactive maintenance, condition monitoring, and a well-planned replacement or repair process.

The goal is to extend bearing life and predict failure before it happens.

Regular Lubrication:

Frequency: Follow manufacturer guidelines. This typically ranges from every 50-100 hours of operation for slow-moving equipment to every 8 hours for continuously rotating equipment.

Method: Add grease slowly while rotating the bearing to ensure even distribution and purge old, contaminated grease. Sufficient grease is applied when it overflows from the seal.

Type of Grease: Use heavy-duty, extreme-pressure (EP) grease as recommended by the manufacturer.

Gear Lubrication: If the slewing bearing has integrated gears, lubricate them separately as their requirements differ from the raceways. Apply small amounts of grease at the point of mesh.

Bolt Torque Checks:

Initial Check: After 100 hours of initial operation, re-check bolt torque.

Subsequent Checks: Every 300-500 hours, and more frequently in harsh conditions (vibration, shock).

Procedure: Wipe bolts clean, apply thread-locking adhesive if replacing, and tighten to the manufacturer's specified pre-tension (often 70% of the bolt material's yield limit). Use Q&T (quenched and tempered) washers; spring washers are prohibited.

Importance: Loose bolts can lead to uneven load distribution, localized stress, and premature failure.

Visual Inspections:

Frequency: At least weekly, or before each operation.

What to look for:

Cracks or damage on the slewing ring.

Signs of biting, gnawing, or surface peeling on gear teeth.

Integrity of seals: replace damaged seals promptly and reset any that have fallen off. Seals prevent contamination of the raceways.

Unusual noise or impact during rotation.

Condition Monitoring (Predictive Maintenance):

Rocking Test (Tilting Clearance Measurement): This is a crucial test to determine the wear of the slewing bearing by measuring the deflection or change in gap between the fixed and rotating structures.

Procedure: Measurements are taken at specific points (e.g., under the jib's center and diametrically opposite) with the jib at minimum and maximum radius (unloaded). A dial gauge is used.

Frequency: Every 6 months, or more frequently if wear approaches tolerance limits.

Tolerance: Compare results to the initial value (from new building stage) and manufacturer's maximum permissible clearance. Exceeding tolerance often necessitates replacement.

Grease Analysis: Take grease samples from the bearing (if sampling ports exist, or by expelling old grease from seals) and analyze for contaminants (wear particles, water), which can indicate internal damage and wear progression.

Vibration Analysis: While less common for the entire slewing bearing, vibration analysis can detect issues with individual rolling elements or gear meshing problems.

Integrated Sensors: Modern "smart" slewing bearings can come with integrated sensors for real-time monitoring of clearance, temperature, and even water content in the lubricant, providing precise data for predictive maintenance.

Corrosion Monitoring: Especially in marine or high-humidity environments, integrated sensors can detect water content in the bearing, triggering alerts for proactive sealing or lubrication.

When a slewing bearing shows signs of significant wear or damage, a decision must be made between repair/refurbishment and full replacement.

Repair/Refurbishment Considerations:

Economic Viability: Often more cost-effective for larger diameter bearings, especially if the damage is minor (e.g., surface scuffing, light staining).

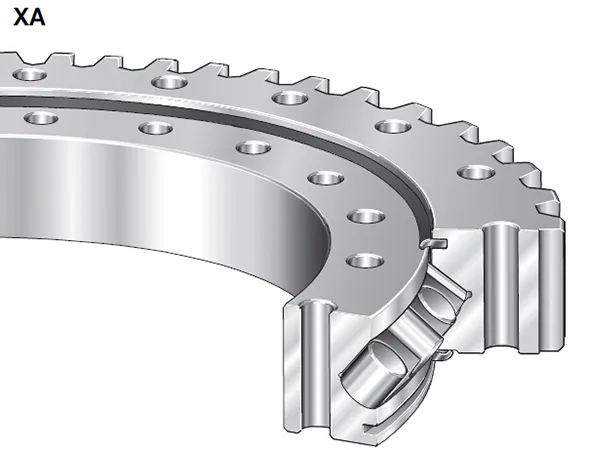

Types of Damage Repairable: Minor surface conditions, some corrosion, indentation, and fine spalling might be repairable through raceway grinding. Replacement of rollers/balls and cages may also be part of refurbishment.

Service Life Extension: Refurbishment can restore a bearing with significant remaining service life (e.g., 30% of calculated life remaining).

Lead Time: Repair might have a shorter lead time than procuring a new, custom-engineered bearing, which can take months to over a year.

Supplier Expertise: Engage specialized bearing repair companies or the original manufacturer for assessment and repair.

Replacement Considerations:

Severe Damage: If the bearing has suffered severe damage (e.g., major cracking, significant deformation), replacement is necessary.

Exceeded Lifespan: When the bearing has exceeded its expected lifespan and shows signs of significant wear, replacement is typically the safest option.

Safety Criticality: For highly critical applications where any risk of failure is unacceptable, replacement may be preferred over repair.

Cost vs. Risk: Evaluate the cost of repair versus the cost of potential downtime and further damage if a repaired bearing fails.

Replacing a large slewing bearing is a complex operation that often requires specialized equipment and expertise. A well-planned, turn-key approach is ideal.

Assessment and Planning:

Thorough assessment of the existing bearing's condition and the equipment's structure.

Review crane data to select the most suitable jacking method.

3D modeling of the crane and design of a jacking frame.

Stress analysis of the jacking frame using predicted loads.

Design of a skidding frame for efficient bearing replacement.

Detailed lift plan and rigging for frame components.

Establish an Inspection and Test Plan (ITP) and Quality Plans.

Preparation:

Ensure the equipment is in a stable position and implement all safety measures (e.g., lockout/tagout, fall protection).

Manage construction of access and load-bearing scaffolding.

Disconnect and remove peripheral components (e.g., slip ring, slew motors, brake packs, gearboxes).

Remove slew bolts.

Perform a controlled trial lift to determine the center of gravity.

Jacking and Bearing Removal:

Assemble and test the jacking system.

Jack up the crane/upper structure.

Check pedestal flatness using a laser and provide a condition report.

Remove the old slewing bearing.

New Bearing Installation:

Storage: Store the new slewing bearing properly (clean, dry, horizontal, in original packaging, lubricated). Avoid long-term storage without re-cleaning and rust-proofing.

Pre-Installation Inspection: Inspect the new bearing for distortion or interference from debris. Ensure mounting surfaces on the main machine are level, smooth, and strong.

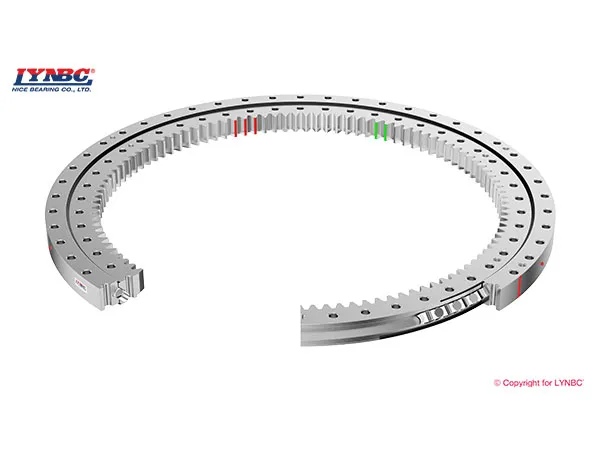

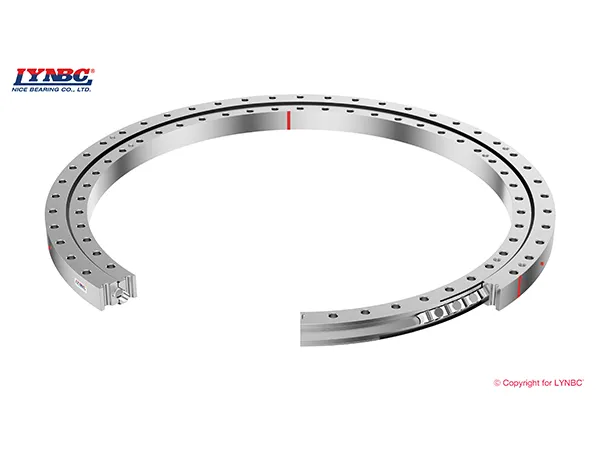

Positioning: Carefully position the new slewing bearing, paying attention to any "soft zones" marked on the bearing (avoid heavy loading on these areas).

Bolt Installation: Install and tension inner and outer slew bolts (e.g., Rotabolts) according to manufacturer specifications. Ensure sufficient pre-tightening force.

Rotate the slewing ring while tightening bolts to identify tight spots.

Lubrication: Fill the bearing with lithium-based grease before and after installation.

Reassembly and Commissioning:

Jack the crane back down.

Re-connect slip ring, slew motors, brake packs, and gearboxes.

Post-Installation Checks:

Full visual inspection.

Check backlash, rocking motion, and teeth flank contact.

Re-check bolt torque after 100 hours of initial operation.

Testing:

Function Test.

Load Test using water bags and load cells (if applicable).

Documentation: Provide a Manufacturing Record Book and Certification Pack.

Maintain critical spares inventory, especially for large, custom-engineered slewing bearings with long lead times.

Implement proper storage solutions for spare bearings, including recertification, interval lubrication, and rotation.Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.