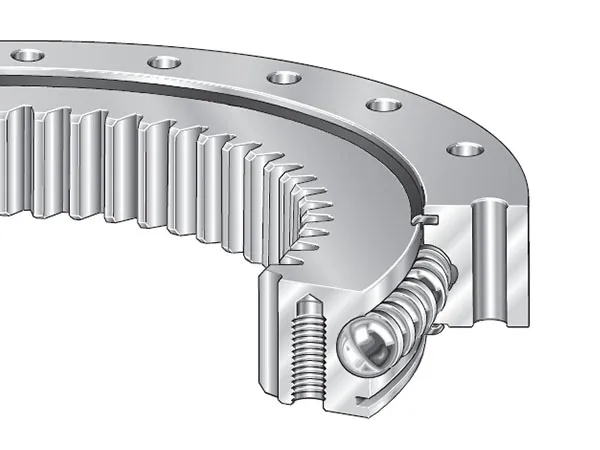

Slewing bearings (also known as turntable bearings) are indispensable key components in modern construction machinery, wind power equipment, port cranes, and other large machinery. Their manufacturing process is complex, involving multiple stages such as material selection, precision machining, heat treatment, assembly, and testing. Understanding the manufacturing process of slewing bearings not only helps improve equipment performance but also provides professional reference for procurement and engineering design. This article will provide a detailed analysis of the manufacturing process and steps of slewing bearings.

As a crucial component of large machinery such as engineering machinery, wind power equipment, and port cranes, the performance of slewing bearings directly depends on material selection and manufacturing precision. High-strength, wear-resistant steel forms the foundation of bearing performance, while the material of the rolling elements determines service life and operational stability.

Outer and Inner Rings: High-strength alloy steel or carbon structural steel, possessing excellent fatigue resistance and machinability.

Rolling Element (Ball or Roller): High-hardness bearing steel, hardened to ensure wear resistance and fatigue resistance.

Lubrication System Materials: Corrosion-resistant and high-temperature resistant, ensuring long-term stable operation.

Through scientific material selection, the load-bearing capacity and service life of slewing bearings can be effectively improved.

The manufacturing process of slewing bearings is a multi-step, sophisticated engineering process designed to ensure the product’s high strength, wear resistance, and long-term reliability.

1. Materials Selection and Cutting

High-quality steel, such as carbon-chromium bearing steel or 50Mn surface-hardened steel, is selected. These materials are known for their high hardness, wear resistance, and toughness.

Cutting: The cylindrical raw material billet delivered from the steel mill is cut to the dimensions required for bearing processing.

2. Forging and Shaping

Billet heating and forging: The billet is heated in a furnace and forged into a disc shape or into a ring shape using a ring rolling mill.

Purpose: Forging is a crucial step in ensuring bearing reliability and lifespan. It makes the internal structure of the material denser, improves grain flow lines, and thus increases the strength and toughness of the steel.

3. Machining

This is the most complex part of the manufacturing process, including:

Rough turning and finish turning: Rough turning of the inner and outer rings removes most of the excess material, followed by finish turning to ensure dimensional accuracy and surface roughness. The dimensional tolerances of the raceway are typically controlled within ±0.01mm.

Milling: Machining mounting holes, keyways, and other structures to ensure positional accuracy.

Raceway Grinding: Grinding the raceway surface to achieve ultra-precise geometry, surface finish, and dimensional accuracy.

Gear Processing: Cutting internal or external teeth on the bearing ring while maintaining raceway integrity.

4. Heat Treatment

Purpose: To improve the strength, durability, and wear resistance of the metal.

Process: Typically employs quenching, tempering, and other processes to achieve the required hardness and mechanical properties.

For example, induction hardening can locally harden the raceway to improve its load-bearing capacity and wear resistance.

5. Rolling Element and Cage Machining

Rolling elements: If steel balls are used, they require rough grinding, fine grinding, and lapping processes to improve dimensional accuracy and surface quality. If rollers are used, cylindricity is ensured through processes such as turning, grinding, and lapping.

Cage: Manufactured according to design requirements by stamping, injection molding, or machining, used to evenly separate and space the rolling elements.

6. Assembly and Debugging

Assembly: Precisely assembling components such as the precision-machined and heat-treated inner and outer rings, rolling elements, and cage. Typically, rolling elements and spacers are inserted one by one through filling plug holes.

Preload Adjustment: Precisely controlling the preload to ensure superior bearing performance.

Seal Installation: Installing seals to ensure good sealing in the working environment.

7. Quality Control and Inspection

Inspection: A critical step throughout the entire manufacturing process to ensure product conformity to design specifications.

Inspection Items: Includes material testing, hardness testing, dimensional inspection, coating inspection, non-destructive testing, and functional testing of the finished product (such as load testing).

Choosing a high-quality manufacturer involves more than just considering materials; it's crucial to focus on manufacturing processes, testing systems, and customization capabilities:

Does the manufacturer possess complete heat treatment, precision machining, and testing equipment?

Does the manufacturer offer customized solutions to meet the needs of different mechanical equipment?

Does the manufacturer have extensive engineering experience and a proven track record of successes?

The manufacturing process of slewing bearings is intricately linked, from material selection, blank machining, heat treatment, raceway machining, precision assembly to testing and protection; each step affects the bearing's performance and lifespan. Mastering these key aspects ensures the production of high-precision, high-reliability slewing bearings, providing robust protection for construction machinery, wind power equipment, and port machinery.

If you would like to learn more about the applications and customized solutions for high-performance slewing bearings, please contact our technical team for professional support for your engineering projects.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.