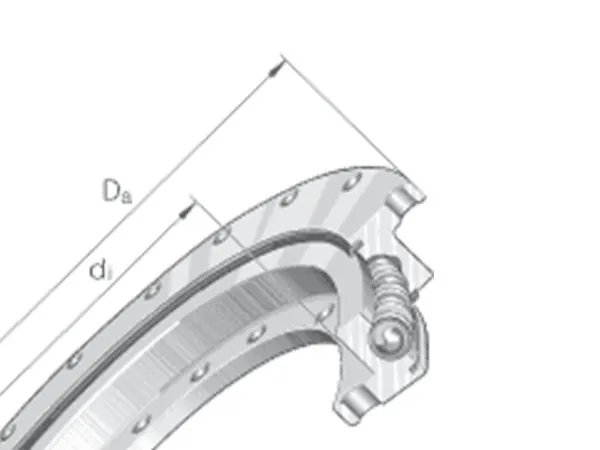

Slewing bearings play a critical role in heavy machinery, construction equipment, wind turbines, and industrial automation systems. Their surface quality directly impacts rotational accuracy, wear resistance, and long-term reliability. Among all factors, surface brightness is often overlooked, yet it significantly affects friction, lifespan, and operational stability.

Below are five proven methods widely adopted in industrial manufacturing to help optimize performance and extend service life.

The material used for slewing bearings determines both their machinability and final surface finish. High-carbon alloy steel and bearing steel are commonly used due to their excellent hardness and wear resistance. Selecting materials with naturally smooth surfaces helps reduce micro-defects during subsequent machining.

Optimization tips:

Prefer bearing steel with uniform hardness after quenching.

Choose materials with fewer oxide layers to ensure better polishing results.

Advanced machining processes are essential for achieving a bright, smooth surface. High-precision turning, grinding, and super-finishing can significantly reduce surface roughness and remove machining marks.

Common surface-improving processes include:

Precision turning – eliminates burrs and prepares the surface for fine machining.

Grinding – increases flatness and reduces roughness values.

Super-finishing / honing – creates near-mirror surfaces for optimal brightness.

Proper control of feed rate, cutting speed, and abrasive selection greatly enhances the final appearance and performance.

Polishing is the most direct way to increase surface brightness. Depending on product requirements, manufacturers can choose mechanical polishing, chemical polishing, or electrolytic polishing. For high-end equipment, additional coating treatments such as chrome plating or nickel plating offer both improved brightness and enhanced corrosion resistance.

Process recommendations:

Control polishing duration and pressure to avoid over-grinding.

Electrolytic polishing is ideal for complex geometries needing uniform shine.

Ensure coating thickness is even to prevent peeling during long-term use.

Even the brightest surface will degrade quickly without proper lubrication. High-quality lubricating oil or grease reduces friction, protects the metal surface from oxidation, and maintains surface smoothness during operation.

Maintenance best practices:

Regularly inspect and replenish lubricants.

Prevent dust, metal chips, and contaminants from entering the contact area.

Apply anti-rust grease when equipment is stored for long periods.

Good lubrication not only preserves brightness but also improves load capacity and bearing lifespan.

Improper installation can scratch or damage the bearing surface, leading to dullness and premature wear. Ensuring correct installation techniques is crucial for preserving the bearing’s surface quality.

Key points:

Use designated installation tools to avoid direct metal collision.

Keep the bearing seat and shaft free from dust or impurities.

Adjust the preload appropriately to prevent friction marks caused by tight or loose fitting.

Improving the surface brightness of slewing bearings requires a combination of high-quality materials, precision machining, professional polishing, proper lubrication, and correct installation. By integrating these methods, manufacturers and equipment operators can significantly enhance bearing performance, reduce friction losses, improve operational accuracy, and extend service life.

A brighter, smoother slewing bearing surface is not just about appearance—it’s an important step toward achieving higher efficiency and reliability in modern industrial applications.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.