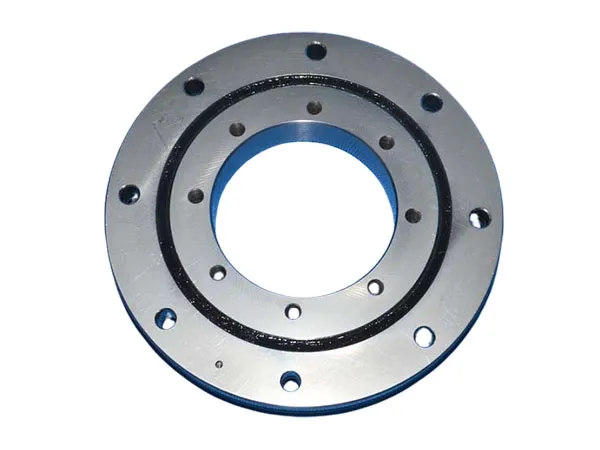

Precision crossed roller bearings are highly specialized components, and their unique design offers a powerful set of advantages, particularly in applications demanding high performance in a limited space.Precision crossed roller bearings offer a multitude of advantages that make them ideal for high-precision applications.

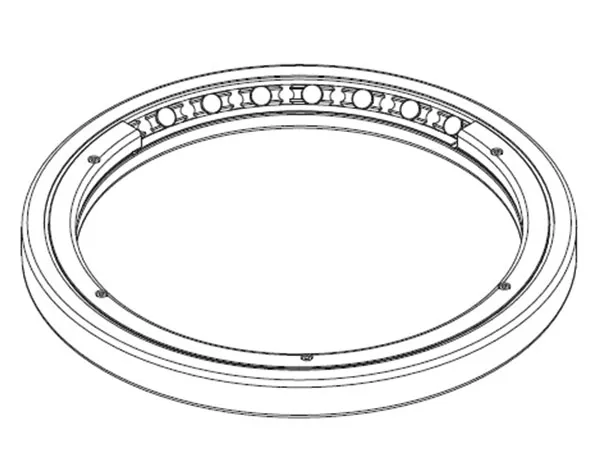

High Precision and Accuracy: The unique design, with cylindrical rollers alternately crossed at 90 degrees, ensures excellent rotational accuracy and minimal deflection under load. This precise arrangement provides a full line of contact between the rollers and raceways, leading to greater stiffness and less elastic deformation compared to point-contact ball bearings. They are crucial for tasks requiring fine motor skills, precise positioning, and smooth, consistent movement.

Exceptional Load Capacity and Rigidity: Crossed roller bearings can handle heavy and complex loads simultaneously, including radial, axial, and moment loads from any direction. This versatile load capacity contributes significantly to the rigidity and stability of the system, which is essential in applications where positional accuracy is paramount (e.g., precision assembly or robotic surgery).

Compact Design and Space Saving: Their orthogonal roller arrangement allows for a highly compact and space-saving design. This is particularly beneficial in applications with limited installation space, such as modern robotics, where miniaturization is a key design goal.

Low Friction and High Efficiency: Crossed roller bearings typically exhibit a low coefficient of friction. This reduces energy consumption, heat generation, and minimizes the difference between static and dynamic torque, contributing to greater overall efficiency and potentially extending battery life in automated systems.

Smooth and Quiet Operation: The non-recirculating design of crossed roller bearings results in extremely smooth motion, as they don't suffer from the pulsations experienced by recirculating bearings. This also significantly reduces noise generation, making them noticeably quieter.

Enhanced Durability and Long Life: Constructed from high-grade materials like steel and stainless steel, precision crossed roller bearings offer excellent resistance to wear and corrosion, leading to a longer operational lifespan and reduced maintenance and downtime. Their consistent contact between the carriage and base also slows down erosion.

Simplified Installation: Many crossed roller bearings feature mounting holes on both inner and outer rings, simplifying installation and often eliminating the need for special housings or fixing plates. Some designs even come with split rings that are bolted together, preventing separation during transportation and mounting.

Versatility in Applications: Due to their unique combination of precision, load capacity, and compact size, crossed roller bearings are widely used in demanding industries such as:

Robotics (joints, articulating arms)

Machine tools (rotating worktables, machining centers)

Medical and laboratory equipment

Semiconductor processing equipment

Clean rooms and vacuum environments

Material handling and automation machinery

Measuring equipment

Optical equipment

In summary, precision crossed roller bearings offer a superior solution for applications demanding high accuracy, heavy load capacity, rigidity, and compact design, making them an increasingly common choice in advanced technological fields.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.