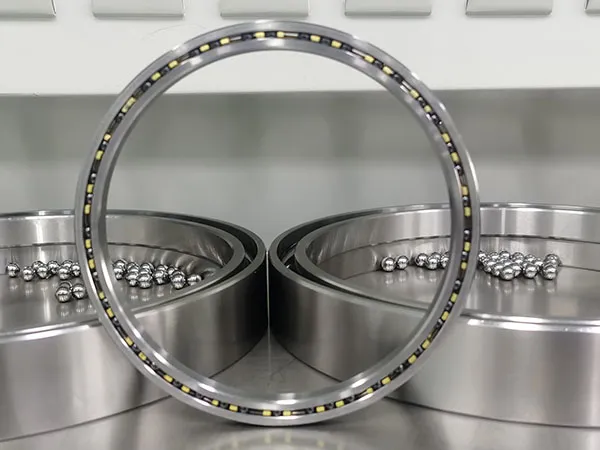

Installing thin section bearings requires precision and careful handling due to their delicate nature. Unlike standard bearings, their thin design makes them more susceptible to distortion if not handled correctly.

Cleanliness: Ensure the shaft, housing, and bearing are meticulously clean and free of any dust, dirt, or foreign particles. Contaminants are a major cause of bearing failure.

Inspection:

Bearing: Visually inspect the bearing for any damage, such as nicks, burrs, or corrosion. Thin section bearings can be challenging to measure accurately with traditional tools (calipers, micrometers) in their free state as they aren't perfectly round. Specialized tools like CMMs (Coordinate Measuring Machines) or air gages are often needed for accurate measurement.

Mating Components: Critically examine the shaft and housing for roundness and flatness. Thin section bearings conform to their mating components, so any imperfections will affect their performance and lifespan. Manufacturers typically provide strict tolerances (e.g., h7 for shafts and H7 for housings).

Lubrication: Thin section bearings usually come with a preservative oil. This should be cleaned off, and the bearing should be lubricated with a suitable oil or grease for your specific application before installation. Sealed bearings are pre-filled with grease.

Tools: Gather the necessary tools. This may include:

Arbor press or hydraulic press (recommended for most installations)

Mounting tools/fixtures (designed to apply even pressure to the correct ring)

Heating equipment (induction heater, oil bath) for shrink fitting

Cooling agents (dry ice) for expansion fitting

Feeler gauges (for checking internal clearance after installation)

Torque wrench (for clamping fasteners)

Clean cloths/wipes

The method chosen depends on the fit (interference or clearance) and the bearing type.

Press Fitting (for Interference Fits):

Principle: This involves pressing the bearing onto the shaft or into the housing.

Important: Always apply force only to the ring that has the interference fit.

Inner Ring on Shaft: Press on the inner ring face.

Outer Ring in Housing: Press on the outer ring face.

Tools: Use an arbor press or hydraulic press with a mounting tool that evenly distributes the force. Never use a hammer directly on the bearing, as this can cause irreversible damage.

Lubrication: Applying a thin film of oil to the mating surfaces (shaft or housing bore) can aid in smooth insertion.

Caution: If both inner and outer rings require an interference fit, use a specialized tool that presses on both rings simultaneously to prevent damage to the rolling elements.

Shrink Fitting (Heating/Cooling for Interference Fits):

Principle: This is the preferred method for larger bearings or those with significant interference fits, as it avoids applying high forces.

Heating the Bearing (for mounting on a shaft): Heat the bearing (typically the inner ring) to expand its diameter. An oil bath or induction heater can be used. Do not exceed 120°C (250°F) unless specified by the manufacturer. Allow the bearing to expand sufficiently, then slide it onto the shaft.

Cooling the Shaft (for mounting into a housing): Cool the shaft or inner ring to contract its diameter. Dry ice or liquid nitrogen can be used.

Important: Ensure all components are at room temperature before tightening any clamping fasteners after the bearing has settled. For cooling, apply rust preventative to the bearing as moisture can condense on the surface.

Axial Sliding/Helical Rotation (for Split Thin Section Bearings or Specific Geometries):

Some specialized split thin section bearings allow for unique assembly geometries.

Axial Passage: The bearing is passed axially along the shaft until it's correctly located. This is generally preferred.

Helical Rotation: The bearing can be rotated onto the shaft in a helical form, similar to threading a nut onto a bolt. This method is suitable only if the bearing groove is close to the shaft end.

Never: Pass the bearing's split radially over the shaft, as this can cause irreversible damage due to excessive stress.

Clamping (Recommended for Most Thin Section Bearings):

Relying solely on a press fit to secure thin section bearings is often insufficient.

Positive Clamping: It's recommended to clamp the bearing into place. The face of the ring being clamped should protrude slightly above the clamping face.

Even Force: Use many fasteners and tighten them in a star pattern to ensure even clamping force. Overlapping clamp rings to form a labyrinth shield can also help retain lubricant and keep out contaminants.

Check Clearance/Preload: Depending on the bearing type (radial, angular contact, four-point contact), checking the internal clearance or preload after installation is crucial. Improper clearance can lead to issues like excessive friction, noise, and premature failure.

Runout: Due to their flexibility, thin section bearings are very sensitive to the roundness and flatness of mating components. Poor mating component geometry can induce runout, affecting performance.

Lubrication (Re-application if necessary): Ensure the bearing is properly lubricated before operation.

Monitoring: During initial operation, monitor the bearing for unusual noise, vibration, or excessive heat, which could indicate installation problems.

Sensitivity to Mating Component Geometry: Their thinness means they conform heavily to the shaft and housing. Any out-of-roundness or non-flatness in the mating components will transfer to the bearing, leading to noise, vibration, and reduced lifespan.

Damage from Improper Force: Applying force to the wrong ring or using impact methods (like a hammer) can easily distort or damage the delicate rings and raceways.

Limited Load Capacity: Compared to heavier section bearings, thin section bearings have a lower load capacity and are more susceptible to damage from overloading.

Vulnerability to Contaminants: Their small clearances make them particularly vulnerable to contamination, which can quickly lead to wear and failure. Proper sealing and cleanliness during installation are vital.

Preload and Clearance: Achieving the correct internal clearance or preload is critical for optimal performance and can be challenging due to the flexibility of the rings.

Always consult the manufacturer's specific installation guidelines for your particular thin section bearing model, as procedures can vary.

Slewing Bearing Care in Wind Turbines: Expert Lubrication & Maintenance

2026-02-25 09:47Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.