Selecting the right precision crossed roller bearing size involves considering several key factors to ensure optimal performance in your application.

Radial Load (Fr): The force perpendicular to the shaft.

Axial Load (Fa): The force parallel to the shaft.

Moment Load (M): The tilting or overturning force.

Crossed roller bearings handle combined loads (radial, axial, and moment) efficiently. Calculate the expected loads and refer to the bearing’s dynamic (Cr) and static (Cor) load ratings.

Inner Diameter (ID): Match the shaft size.

Outer Diameter (OD): Ensure it fits within the housing.

Width (Height): Check space constraints.

Standard sizes range from small (e.g., 10mm ID) to large (e.g., 500mm ID).

Precision bearings (e.g., ABEC-5, ABEC-7, P4, P2) have tighter tolerances.

For high rigidity, select a bearing with preload (eliminates internal clearance).

Check the limiting speed (rpm) based on lubrication and cage material.

Polyamide cages allow higher speeds than steel cages.

Inner/Outer Ring Rotation: Decide if the inner or outer ring rotates.

Split vs. Non-Split Design: Split types (e.g., XR series) are easier to install.

Lubrication: Grease (standard) or oil (high-speed).

Sealing: Optional seals for dust/moisture protection.

Material: Stainless steel (corrosion resistance) or standard chrome steel.

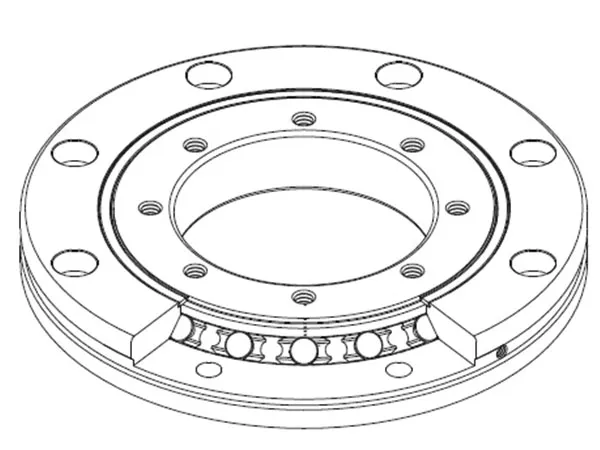

Common precision crossed roller bearing series:

RB / RA (Standard)

XR (Split Inner Ring)

CRBH (Thin-Type)

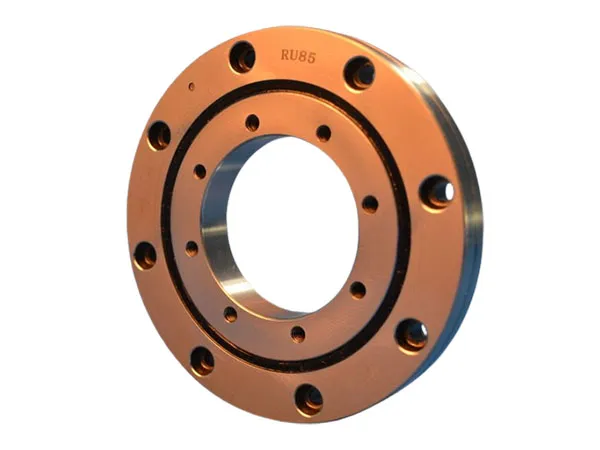

RU (Non-Split)

RE / SX (High Rigidity)

Compare load ratings, dimensions, and tolerances (e.g., IKO, THK, NSK, Schaeffler).

Use life calculation formulas (e.g., ISO 281) for expected bearing life.

Example Selection Process:

Application: Rotary table for CNC machine.

Loads: Fr = 2000 N, Fa = 1500 N, M = 100 Nm.

Shaft Size: 50mm → ID = 50mm.

Precision Needed: ABEC-7 (P4).

Speed: 300 rpm → Standard grease lubrication OK.

Choice: RB5008 (50mm ID, 80mm OD, 15mm Width) or XR305 (50mm ID, 80mm OD, Split Design).

Final Tips:

If unsure, consult a bearing supplier with load & speed data.

Consider custom sizes for unique applications.

Ensure proper installation alignment to maximize bearing life.

By following these steps systematically, you can confidently select the right precision crossed roller bearing size for your application's specific needs.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.