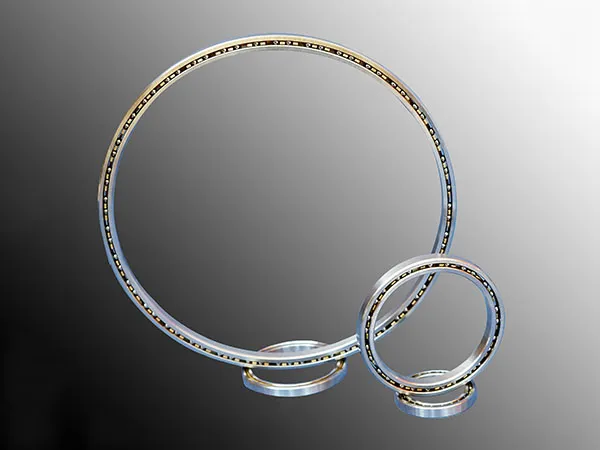

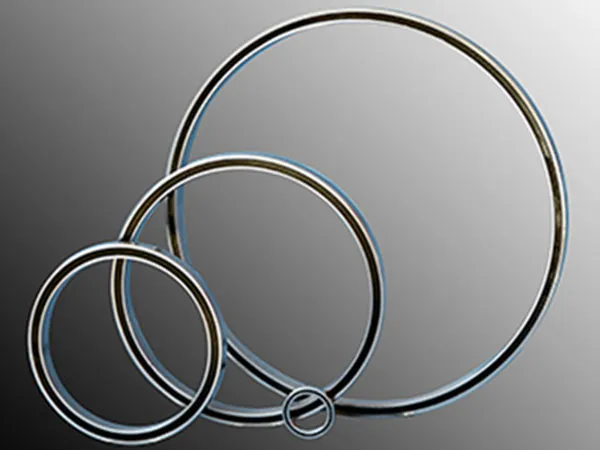

Thin section bearings are designed to be compact and lightweight, making them ideal for applications where space and weight are critical. However, their delicate nature requires specific maintenance practices to ensure their longevity and optimal performance.

Cleanliness is Key: Ensure the housing and shaft are free of any debris, dust, or contaminants before installation. Even small particles can significantly impact bearing performance and life.

Use Appropriate Tools: Never use a hammer or direct impact to install thin section bearings. Use an arbor press or specialized bearing installation tools that apply even pressure to the inner or outer ring, depending on the fit.

Avoid Brute Force: Forcing a bearing into place can deform the rings or damage the rolling elements, leading to premature failure. If a bearing doesn't slide on easily, re-check the shaft or housing dimensions.

Correct Orientation: Ensure the bearing is installed with the correct orientation, especially if it's a shielded or sealed type.

Right Lubricant: Use the type of lubricant recommended by the bearing manufacturer. This could be grease or oil, and the specific type will depend on the bearing's operating conditions (speed, temperature, load).

Optimal Amount: Over-lubrication can be as detrimental as under-lubrication, especially for high-speed applications. Excess grease can lead to increased friction, heat generation, and churning, while insufficient lubrication causes wear.

Regular Re-lubrication: Establish a re-lubrication schedule based on the operating environment, bearing type, and manufacturer recommendations. Factors like temperature, contamination, and speed will influence this frequency.

Cleanliness During Lubrication: Always ensure that the lubrication equipment and the area around the bearing are clean to prevent contaminants from entering the bearing.

Seals and Shields: Ensure that seals and shields are in good condition and functioning properly to prevent the ingress of dust, moisture, and other contaminants.

Clean Environment: Maintain a clean working environment, especially during installation and maintenance.

Proper Storage: Store new bearings in their original packaging in a clean, dry area until ready for use to prevent contamination and corrosion.

Regular Checks: Periodically inspect bearings for signs of wear, damage, or contamination. Look for discoloration, excessive noise, vibration, or increased operating temperature.

Noise and Vibration Analysis: Use vibration analysis tools to detect early signs of bearing damage. Changes in noise levels or vibration patterns can indicate a problem.

Temperature Monitoring: Monitor the bearing's operating temperature. An unexpected increase in temperature can be a sign of insufficient lubrication, excessive load, or damage.

Visual Inspection: Look for any visual damage such as dents, nicks, or corrosion on the bearing rings or rolling elements.

Gentle Handling: Thin section bearings are delicate. Handle them with care to avoid dropping or impacting them.

Corrosion Protection: If bearings are stored for extended periods, ensure they are properly protected against corrosion. This may involve applying a thin layer of protective oil or storing them in moisture-free environments.

Respect Load Ratings: Never exceed the bearing's specified dynamic and static load ratings. Overloading can lead to premature fatigue and failure.

Shock Loads: Avoid exposing thin section bearings to sudden shock loads, as these can cause brinelling (indentations) on the raceways.

Thin section bearings are precision components with small cross-sections, so they demand cleanliness, correct lubrication, careful handling, and regular monitoring.Proper installation and environmental protection are key to maximizing their lifespan.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.