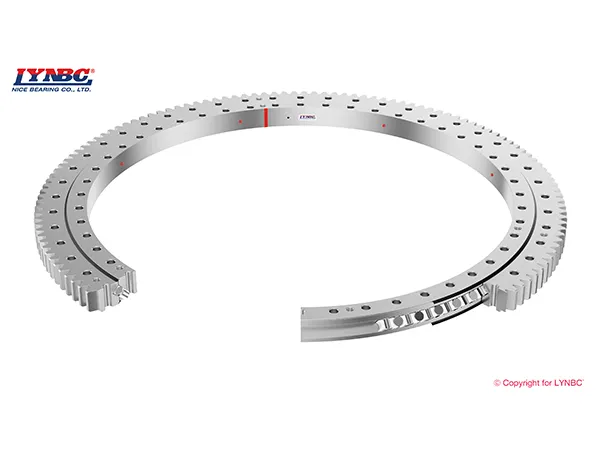

Slewing bearings, also known as slewing rings, are crucial components in heavy machinery. They allow for rotational movement while supporting significant axial, radial, and moment loads. Proper installation and maintenance are essential for their longevity and reliable operation. This guide covers the key steps for both.

The installation process is critical for the bearing's performance. Deviations can lead to premature failure.

1. Preparation

Inspection: Before installation, inspect the bearing for any damage, such as dents, rust, or improper sealing.

Surface Preparation: Ensure that the mounting surfaces of both the machine's structure and the slewing bearing are clean, flat, and free from burrs. The flatness of these surfaces directly impacts the load distribution on the bearing's raceways. A non-flat surface can cause uneven loading and shorten the bearing's life.

Bolt Holes: Clean the bolt holes of any debris or old sealant. This ensures that the bolts can be tightened correctly and securely.

2. Mounting

Lifting: Use appropriate lifting equipment to move the bearing. Be careful to distribute the weight evenly to avoid distorting the bearing.

Placement: Gently lower the bearing onto the mounting surface. Make sure the bearing is correctly aligned with the bolt holes.

Securing: Install all bolts, but do not tighten them completely. Start by hand-tightening all bolts, then use a torque wrench to tighten them in a crisscross or star pattern. Follow the manufacturer's specified torque sequence and values to ensure even pressure. Overtightening or improper tightening can deform the bearing and lead to failure.

3. Gear Mesh Adjustment (If Applicable)

If the bearing has an internal or external gear, the gear mesh needs to be checked. The backlash (the clearance between the teeth of the two gears) is a critical parameter. A small amount of backlash is necessary for smooth operation and thermal expansion, but too much or too little can cause excessive wear or binding. Follow the manufacturer's recommendations for the correct backlash.

Routine maintenance is the key to extending the service life of a slewing bearing. It's a proactive approach that prevents costly downtime and repairs.

1. Lubrication

Grease: Slewing bearings require regular lubrication with high-quality, lithium-based, or synthetic grease. The grease fills the raceways, reducing friction and protecting against corrosion.

Frequency: The lubrication frequency depends on the operating conditions, such as load, speed, and environmental factors. For most applications, it's recommended to lubricate the bearing every 100 operating hours. However, it's best to follow the manufacturer's specific guidelines.

Procedure: When lubricating, rotate the bearing to ensure the grease is evenly distributed throughout the raceways. Pump grease into the grease nipples until fresh grease appears at the seal. This indicates that old, contaminated grease has been purged.

2. Bolt Retightening

Initial Check: The mounting bolts may loosen during the initial hours of operation due to settling. It is crucial to re-torque the bolts after the first 100 hours of use.

Periodic Checks: After the initial check, inspect and re-torque the bolts every 500-1000 operating hours, or as recommended by the manufacturer. Loose bolts can cause uneven load distribution and damage the bearing or the machine structure.

3. Inspection and Monitoring

Visual Check: Periodically inspect the bearing and its seals for signs of wear, damage, or leaks. A damaged seal can allow contaminants like dust and water to enter the bearing, which can be very destructive.

Auditory Check: Listen for unusual noises during operation. Grinding, clicking, or cracking sounds can indicate damage to the raceways or gears.

Backlash Check: If the bearing has a gear, check the gear backlash regularly. Any significant change in backlash could indicate wear or damage.

By following these installation and maintenance guidelines, you can ensure the safe and efficient operation of your slewing bearing, minimizing the risk of failure and maximizing its service life.

Thin Section Bearing Corrosion Protection Methods: Maximizing Performance and Longevity

2026-01-28 08:55How to Extend the Life of Thin Section Bearings: Practical Tips for Precision Machinery

2026-01-23 09:37How to Choose the Right Thin Section Bearing for High-Speed Applications

2026-01-15 14:37Thin Section Bearing Failure Analysis and Practical Solutions for Long-Term Reliability

2026-01-09 11:37Address: Lianmeng Road, Jianxi district, Luoyang City,Henan province.

E-mail: info@lynicebearing.com

Phone: +86-379-60689957

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.